- Metalnastri Anticorrosion Systems

- Via Papa Giovanni XXIII, 11/A, 20053 Rodano Millepini (Milano)

- +39 02 92592060

Monitoring

In order to determine the performance of the cathodic protection of concrete structures, a monitoring system should be planned.

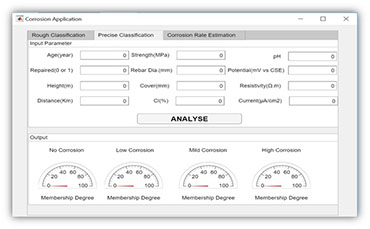

Monitoring of Sacrificial Anode Cathodic protection (SACP) systems can be done using different methods. According to the ISO 12696:2016 standard, the cathodic protection system performance shall be determined by measuring the steel/concrete potential, using reference electrodes. Coupons and macro-cells are additional monitoring approaches. For some cases, permanently installed monitoring systems are being used and instrumentation is principally required to measure and save direct current and voltages

We are able to provide different options for monitoring of cathodic protected concrete structures according to the customers desire;

- Manual monitoring unit

- Automated monitoring unit with manual data transfer:

- Fully automated remote monitoring unit

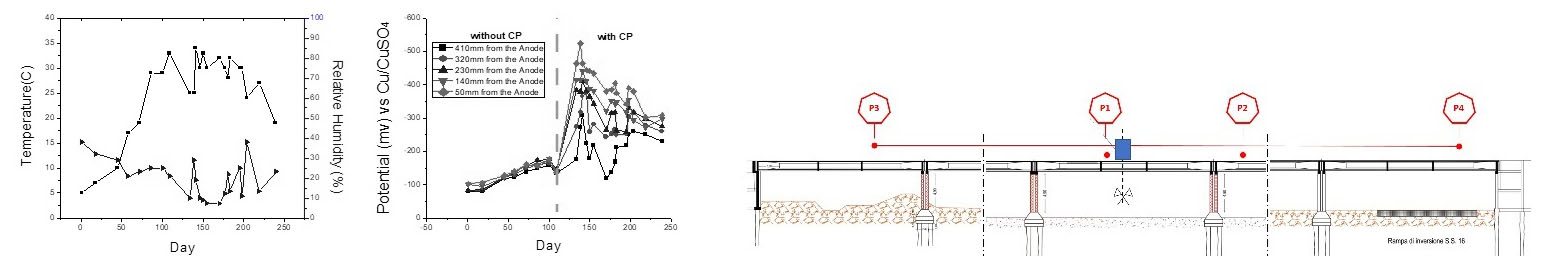

Our fully automated remote monitoring systems are able to track both the anodic current and steel potential. Therefore, the system is designed to monitor the site environmental conditions and anodic current being provided to a structure. The remote system can provide periodic readings (e.g. min, hour, or day) enabling trends to be observed that would not normally be observed using traditional assessment methods. In addition to monitoring events, remote monitoring systems are capable of providing a continuous log of data obtained from a variety of sensors (e.g. temperature, humidity, strain, load, deflection, etc.). This provides an unprecedented amount of information that can enable to data subjects to better understand the behavior of the environmental factors and their influence on the durability of the structure, as well as to keep the main structural parameters under control.

Therefore, the use of a remote monitoring system not only allows continuous access to data, but has the ability to immediately identify possible problems, allowing to take prompt action with a consequent significant cost savings